Composite Floor Deck

Featured Features

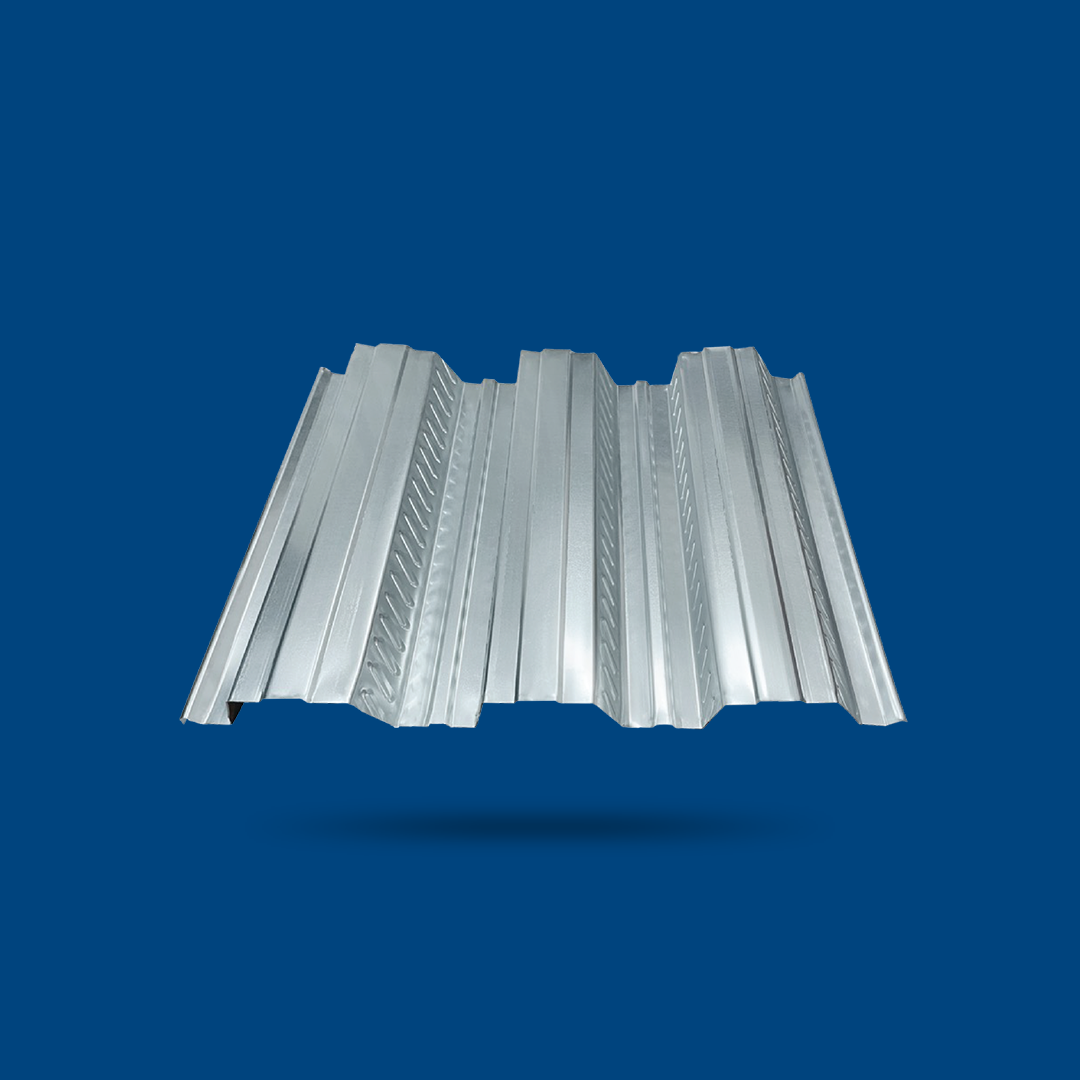

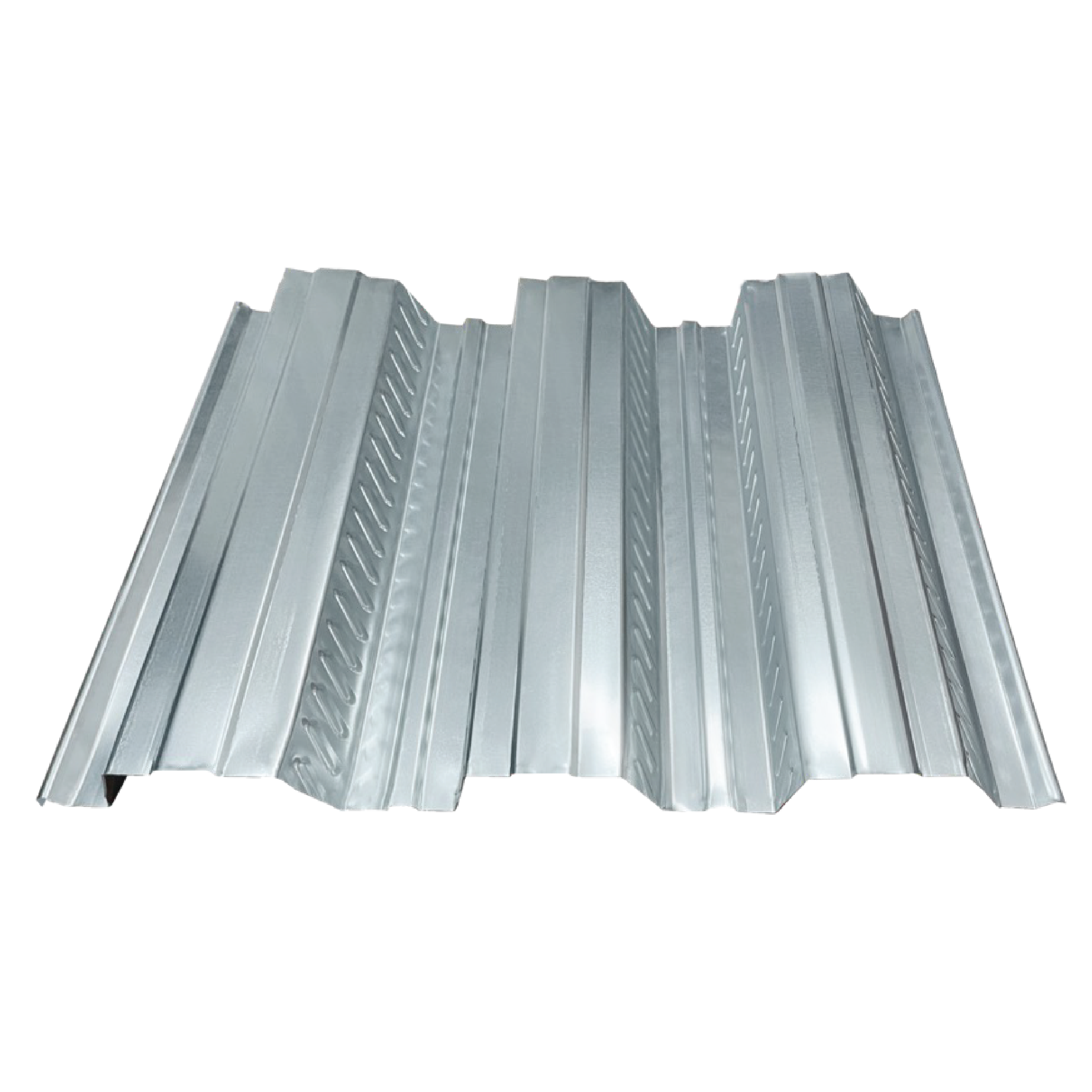

Concrete trapezoid made of galvanized or painted galvanized hot dip sheet.

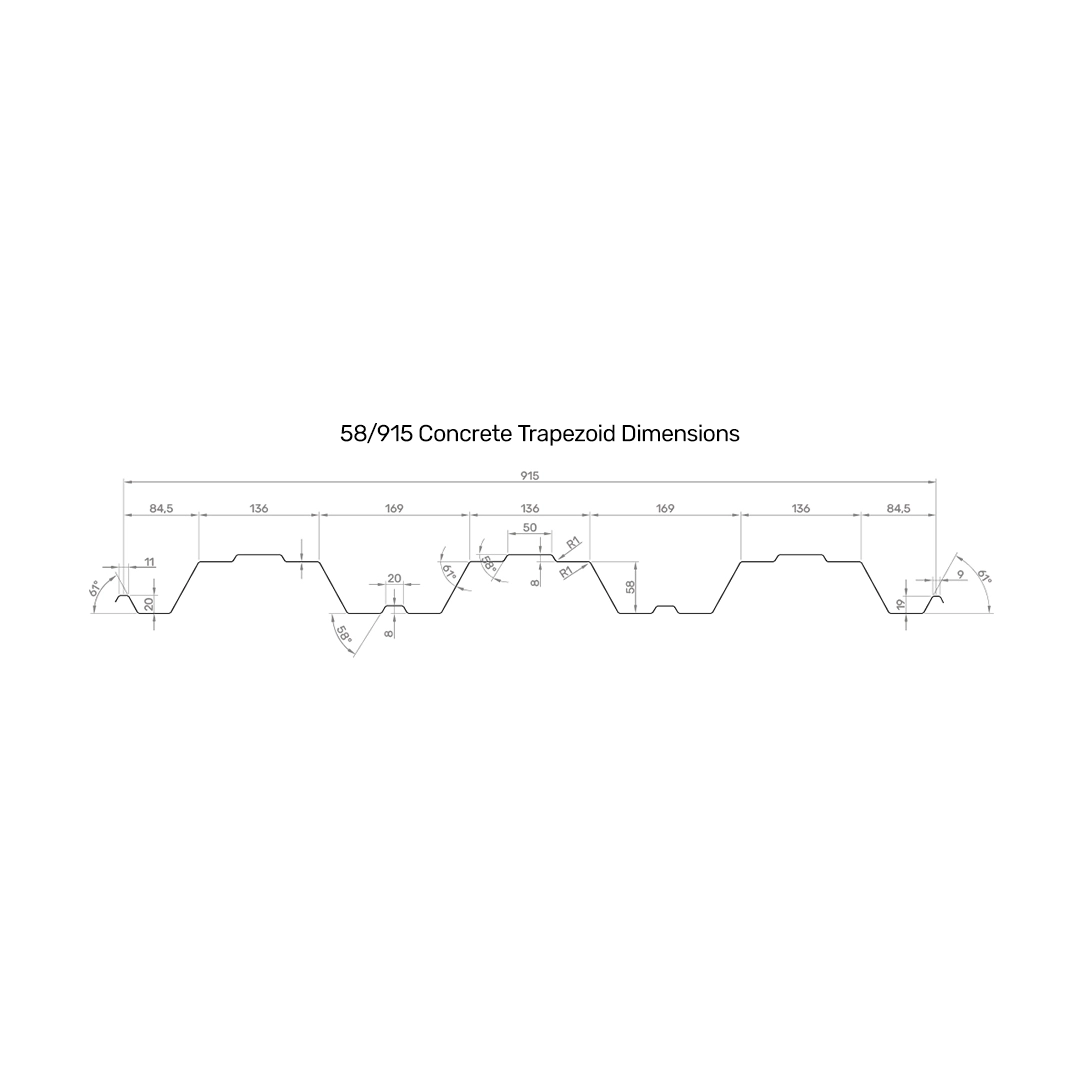

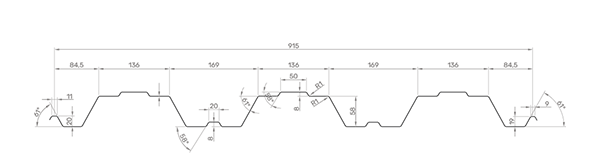

It represents forming galvanized and painted galvanized sheet roll at 58/915 section. It is made in the form of 3-top from 1200 mm wide roll.

UMS 58/195 concrete trapezoid is designed for use in composite floorings. These materials serve as a platform for the workers and materials during the course of construction, and as a mold for wet cast concrete. Afterwards, when the concrete is set and gains sufficient strength, and adherence to the concrete is ensured, they help composite work by meeting all or part of tensile component in the flooring.

Trapezoidal plate behaves differently during mold period and composite process. During the mold period, trapezoidal sheet is exposed to bending and shearing effects because of the loads on it. During composite process, trapezoidal sheet generally forms the tensile component of composite section, depending on the location of neutral axis. However, even if rarely, in some adverse situations it provides resistance to pressure and tensile together with concrete.

These two behaviour patterns mentioned above are analyzed separately and related calculation tables are formed accordingly. Eurocode 4 “Design of Composite Steel and Concrete Structures” of European Union standards is taken as a principal reference in calculations. It is accepted that shear between concrete and steel in the behavior during the composite process is prevented. It is also considered that in the composite work all shear force formed in the section is met by concrete component.