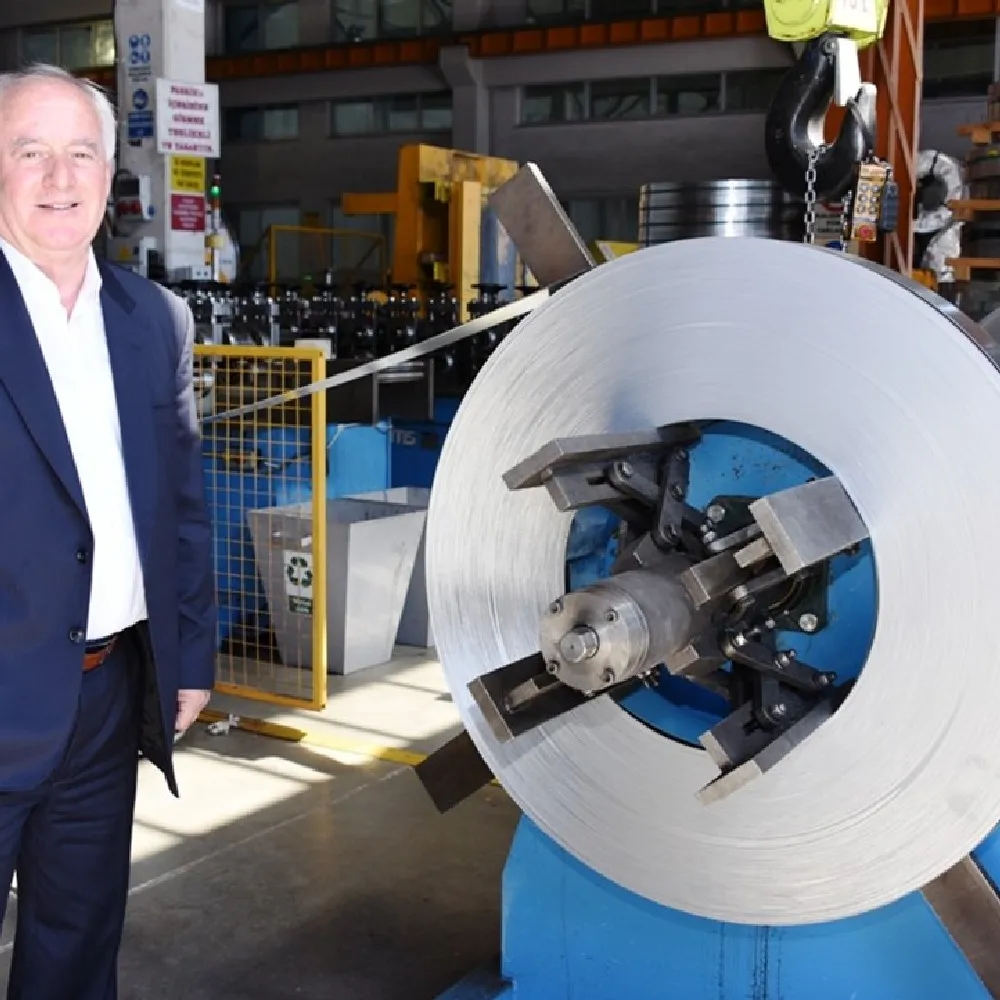

Our General Manager Hakkı Usta in the OSTİM Organized Industry Newspaper

The Measure of Locality is the Turkish Design

After graduating as a mechanical engineer, Hakkı Usta started his professional life at the General Directorate of Highways. He worked as an academician for a while and then returned to the field, engaging in production across a wide range of industries, from automotive to defense. He has contributed to product development and worked on localizing engines.

Bringing his extensive experience to the Turkish economy together with his two sons at UMS Çelik, which operates in OSTİM, Usta defines locality as follows:

"The design must be 'Turkish'; the proportional value of the design and the materials used is a measure of locality."

Mr. Hakkı, could you introduce yourself?

I graduated as a mechanical engineer from Karadeniz Technical University’s Faculty of Mechanical Engineering in 1974. Afterward, I received machine basic course training at the General Directorate of Highways. I completed my military service as an engineer at a tank factory.

After my military service, I became an assistant professor in the Internal Combustion Engines Department of the Faculty of Mechanical Engineering at Karadeniz Technical University. I taught undergraduate courses such as Motor 1 Theory, Motor 2 Theory, Laboratory, and Design Studies.

During this time, I was awarded a UNESCO scholarship and went to England, where I conducted scientific research in the Fuel Technology Department at the University of Sheffield. Unfortunately, due to the circumstances at the time, I had to leave the university after returning to Turkey.

What did you do after leaving academia?

I worked as a Motor Line Manager at the John Deere tractor factory for a year and a half. Later, I took on the same role at Ford Otosan’s İnönü Factory in Eskişehir. I was involved in the localization project of the Transit diesel engine. As part of this project, I went to Germany for training in programming and operating CNC machines.

After returning from Germany, we manufactured and began producing cylinder blocks, cylinder heads, crankshafts, and connecting rods.

Since I had a goal to continue my career in Ankara, I accepted a job offer from Nurol Makine ve Sanayi A.Ş. as a Manufacturing Manager. Nurol Makine ve Sanayi A.Ş., in partnership with the American company FMS, was producing armor systems, filtration systems, and weapon systems for armored personnel carriers. I worked there as a Manufacturing Manager for five years.

When was UMS Çelik founded?

In 1999, after my son graduated from Istanbul Technical University, we established a company trading galvanized sheet metal. Our main goal was always to move towards investment and production. The company quickly became successful in sheet metal sales, and in 2005, we established a steel service center in OSTİM.

Our steel service center includes slitting, trapezoidal sheet production, and flat sheet production lines. Our machines can process 20-ton galvanized or pre-painted galvanized steel sheets and shape them according to customer requirements. We started with 8 employees, and today we have 65 employees working in our steel service center.

What is your production capacity?

From the beginning, we have always maintained a high production capacity. Our primary goal was to meet customer demands as quickly as possible and establish success in this area.

For this reason, we invested in high-speed machines with precision and repeatability capabilities. The machines we purchased at the time were the latest technology, and even today, they are among the best in Turkey.

With a two-shift system, we have an annual processing capacity of 150,000 tons of material. Understanding the importance of working with standards, we obtained the TSE EN ISO 9001 quality production certificate in 2006. We integrated our system with Western-standard production technologies.

In 2013, to expand our customer base and move toward final product manufacturing, we began producing gypsum board profiles and accessories. Along with this production, UMS became a company that not only manufactures profiles in its own developed cross-sections but also designs and manufactures its own machines.

What are your company’s production categories?

We can categorize our production into three main areas:

-

Steel service center production – including slitting, trapezoidal sheet production, and flat sheet production.

-

Gypsum board profile production – We are the company with the highest production capacity in Turkey in this segment.

-

Gypsum board profile accessories – All of our products are TSE-certified, and we are the only company in Turkey with an Environmental Product Declaration (EPD) certificate for our products. Thanks to this certificate, our products are preferred in all LEED-certified buildings.

What kind of industry is steel?

The steel industry, particularly the flat steel market, is one of the most volatile industries, highly sensitive to economic fluctuations, with sharp upward and downward trends.

As a result, manufacturers in the industry are constantly in competition. This competition negatively impacts steel service centers like ours. Since potential customers are often involved in large government-related projects, payment delays in the construction industry create significant slowdowns, causing major damage to the sector.

What does domestic and national production mean to you?

When I think of domestic production, I primarily consider this: The design must be Turkish. The proportional value of the design and the materials used is a measure of locality. Auxiliary materials may be sourced from abroad, and we should not get stuck on that.

For complex and expensive products that require highly advanced production technologies, we may need to import certain components. However, intellectual property and patents must belong to us. We must be the ones to develop them. That is the mindset we should adopt.

What is the biggest challenge for SMEs?

The biggest challenges are education, a visionary approach, and financial structure. Entrepreneurs and industrialists must be educated and well-equipped. The work they do must be high-quality, and the workplaces they operate must comply with occupational health, safety, and environmental standards while maintaining continuous improvement.

When these elements are lacking, we see businesses that become inward-focused, struggle with challenges, and damage the economy when financial instability arises.

To prevent this, companies must implement quality standards without compromise, leverage technology, and adopt R&D-supported production methods to enhance product diversity and quality. Companies that adopt these approaches will reach a level where they can offer products to the market at competitive costs.

Do you have difficulty finding qualified labor?

Yes, I struggle a lot, especially when it comes to workers. Unfortunately, we can never find the exact qualifications we seek. We train all our employees in-house, provide them with vocational competency training, and develop technological applications through orientation programs.

What do industrialism and entrepreneurship mean to you? Why do you manufacture?

To me, an entrepreneur is someone who leverages their knowledge and structure to create new business opportunities, generate employment, and contribute to their country.

I believe manufacturing is a different kind of passion. Transforming knowledge into a systematic structure has always been a source of pride for me. An entrepreneur must have creativity, knowledge, reliability, and risk management skills. Turning R&D capabilities and ideas into reality and providing employment brings a unique sense of fulfillment.

Finally, what does OSTİM mean to you?

OSTİM means bread, work, employment, and the future.